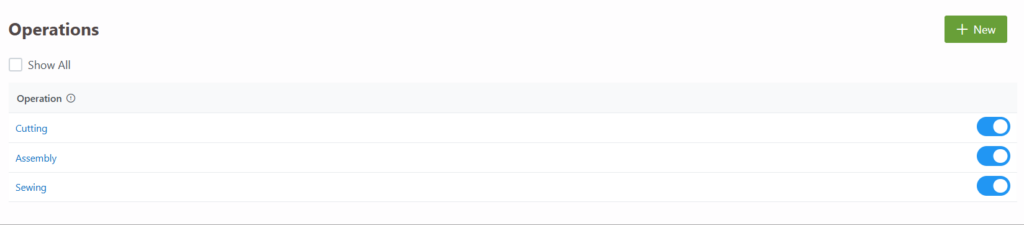

Operations

Operations represent the production stages that products go through in the firm. The Operations screen is used to list the operational processes that will be used in work orders.

For example:

- For a t-shirt manufacturer: Cutting, Sewing, and Ironing can be defined as operations.

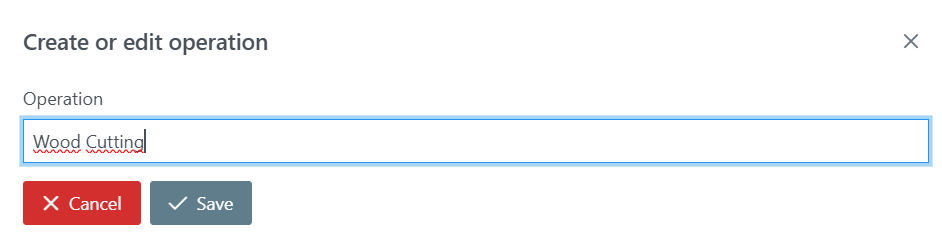

- For a furniture manufacturer: Wood Cutting, Lamination, Varnishing, and Assembly can be defined as operations.

Adding a New Operation

To add a new operation, click the + New button on the Operations screen and fill in the required details.

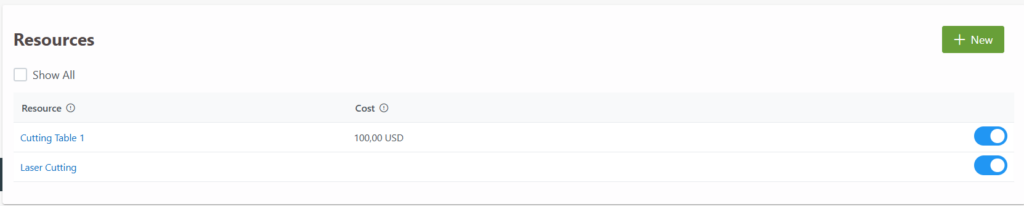

Resource

A resource refers to the stations or operators performing the production stages.

For instance:

- Examples of stations: Cutting Table 1, Cutting Table 2, Laser Cutting (Outsourced).

Adding a New Resource

To add a new station:

- Go to the Settings page.

- Select the Stations section.

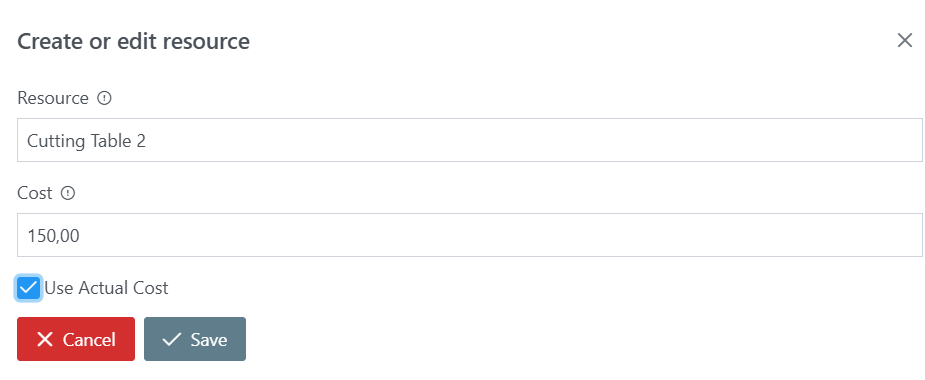

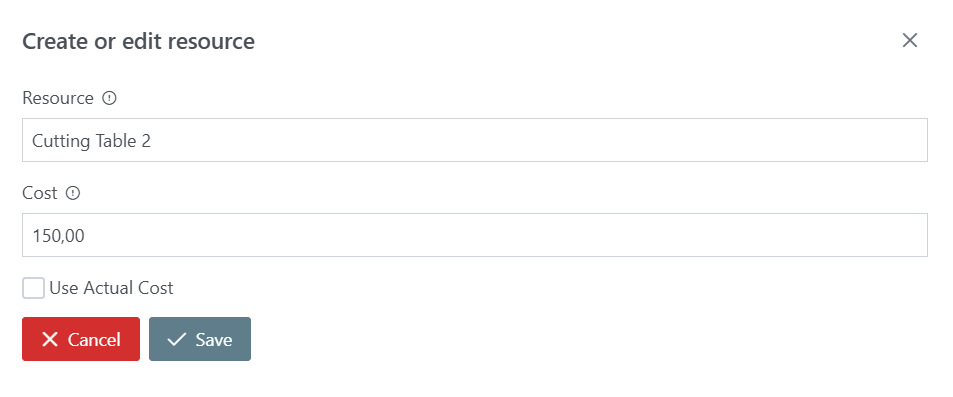

- Click the + New button to open the resource creation screen.

Adding Costs to a Station

If you want to include the usage fee of a resource in the production cost:

- In the Resource Creation Screen, you can add a fixed cost for each resource.

- This fixed cost is added to the production cost each time the resource is used in an operation.

Actual Costs

If the Actual Cost option is selected on the Station/Resource Creation Screen, the production cost will be calculated based on the usage duration of the resource. This provides a more precise calculation of resource costs during production.