Planning Screen; is a screen where products and semi-finished products that are not in stock and need to be produced in active orders are listed, as well as raw materials and semi-finished products that are not in stock in products to be produced in active work orders. In short, it is a screen where you can easily follow up on the list of requirements for current production and sales. Purchase requests and production orders can also be easily given through the planning screen.

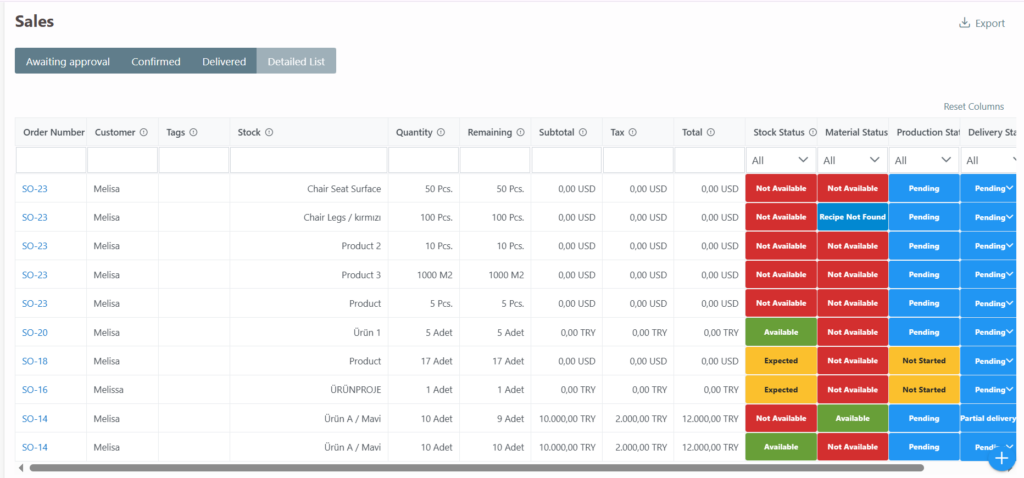

For example; in the image below, you can see all active orders on the orders screen.

We see that the product named Product is in the order with code SO-23 and its stock status is negative. We see that the product named Ürün 1 is in the order with code SO-20 and its stock status is in stock. Now let’s go to the planning screen and try to fully understand the logic.

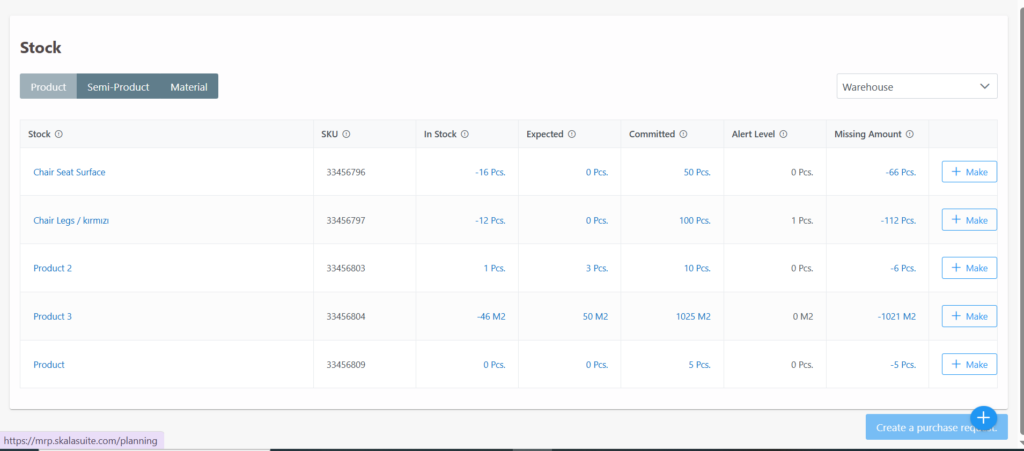

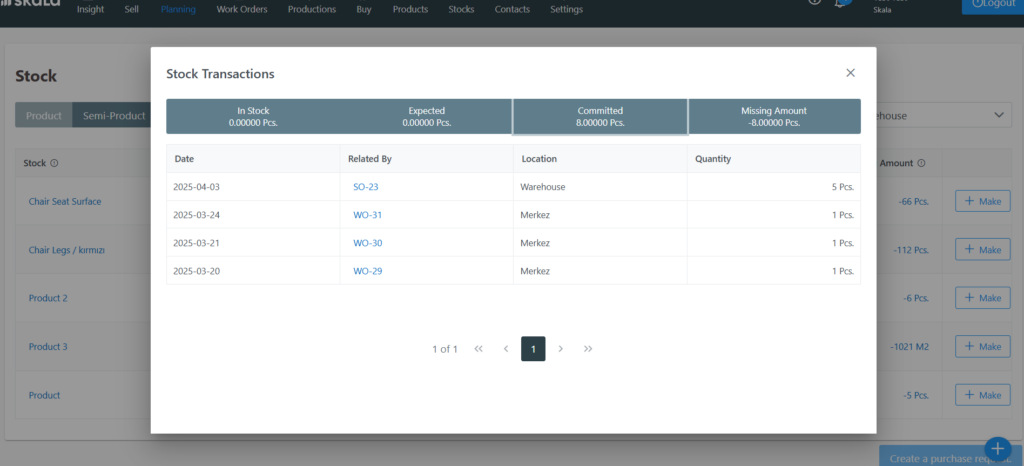

Product is on this list but Ürün 1 is not, the reason for this is that Ürün 1 is not in stock in sufficient quantities to complete the order, meaning it needs to be produced, which we can see on this page. Ürün 1 is not included in this list because we have the requested quantity in our order. If we look at the stock movements for Product;

We also see that we need to produce 5 units for the order code SO-23. Let’s place a work order by pressing the produce button next to Product on the planning screen.

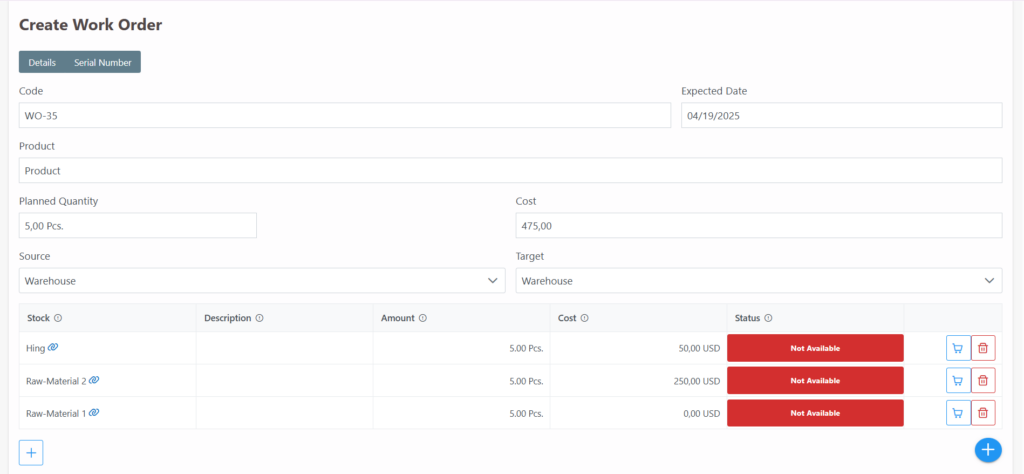

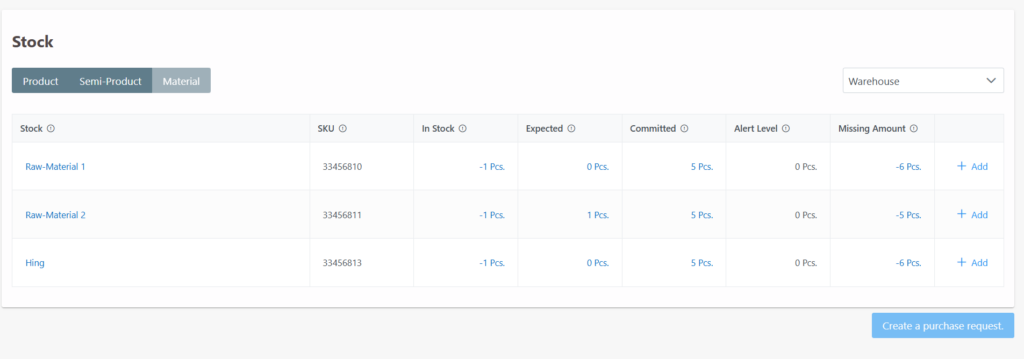

The system directs us directly to the work order creation screen and as we see on the planning screen, the quantity we need to produce is also full. We also see that we do not have any of the raw materials named Raw Material 1, Raw Material 2 and Hing in stock for the production of Product. Now let’s save this work order and this time go to the raw material section on the planning screen.

Now that we have given a work order, the raw materials we need are listed on the planning screen. After clicking the add button on the right, you can quickly create a purchase from the planning screen with the create purchase request button below.

To summarize, the planning screen is a screen where our active needs are listed, so it is a useful section in terms of facilitating production processes.