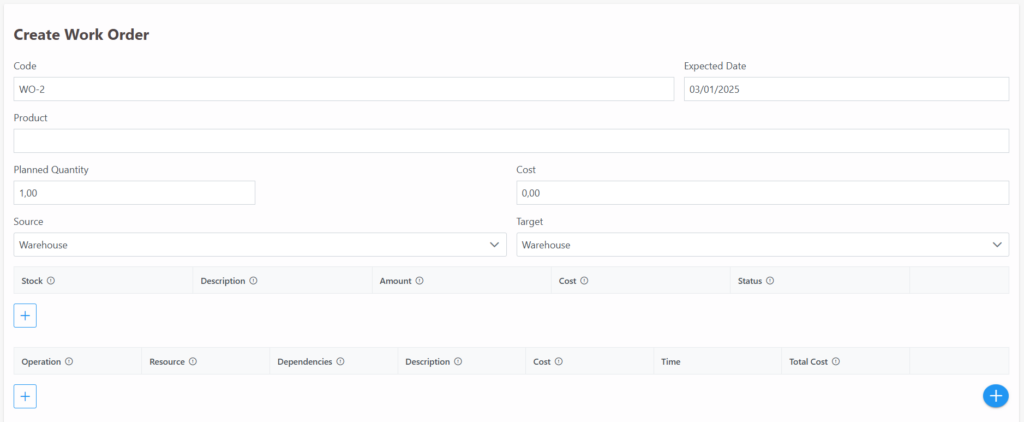

In Skala, a work order can be created both for an order and for stock. When a new work order is to be created, the option to create a work order is selected from the plus button at the bottom right.

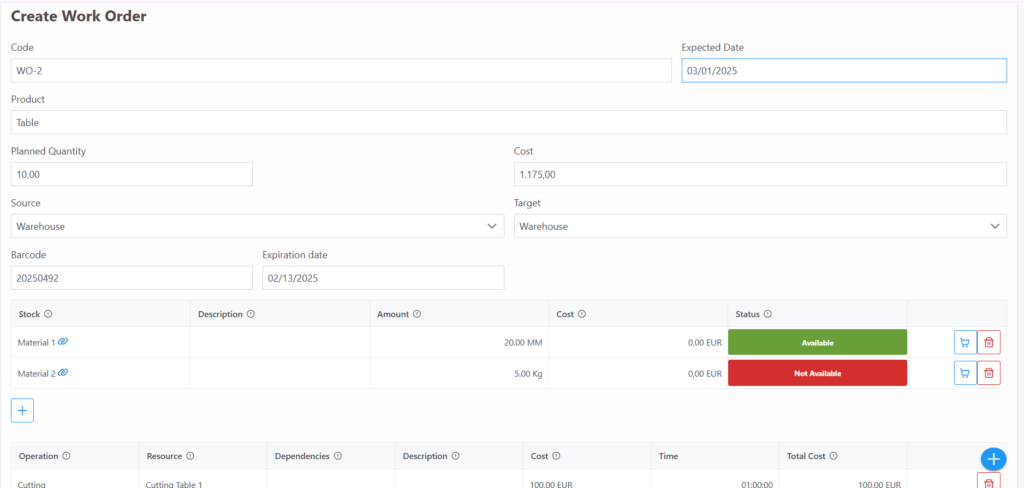

In the opened screen, the name of the product to be produced is entered first. If the product has a recipe and operation information in its stock card, the recipe and operation sections will be automatically filled by the system once the product name is written. If the recipe or operations are not specified in the stock card, raw materials/semi-finished goods to be used in the production of the product can be added by clicking the plus button. Similarly, operations can be added by clicking the plus button in the operations section.

The planned quantity field is where the desired quantity to be produced is written, and the source and target locations are selected as the locations where raw materials will be used and where the produced product will be entered.

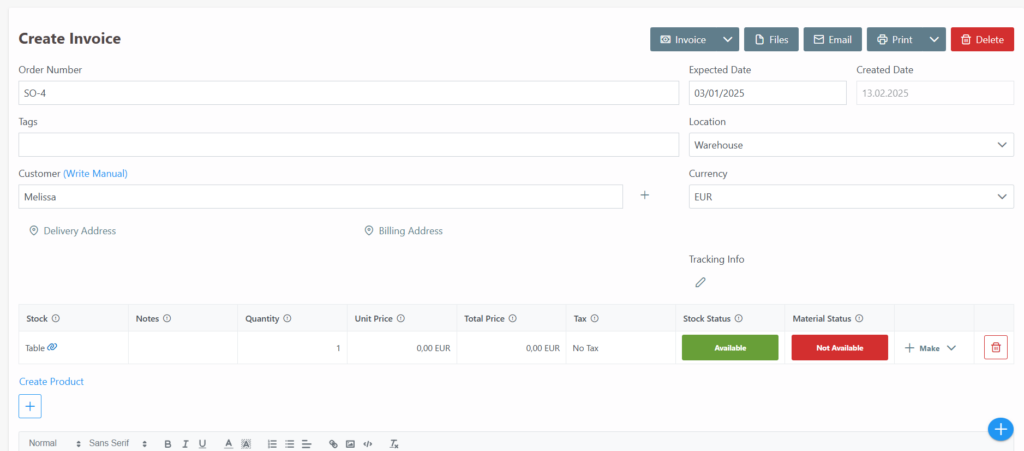

After making the adjustments, the work order is saved by clicking the save button located at the bottom left. Another method of creating a work order is creating a work order based on an order. After creating and saving an order in Skala, the “Produce” button will appear.

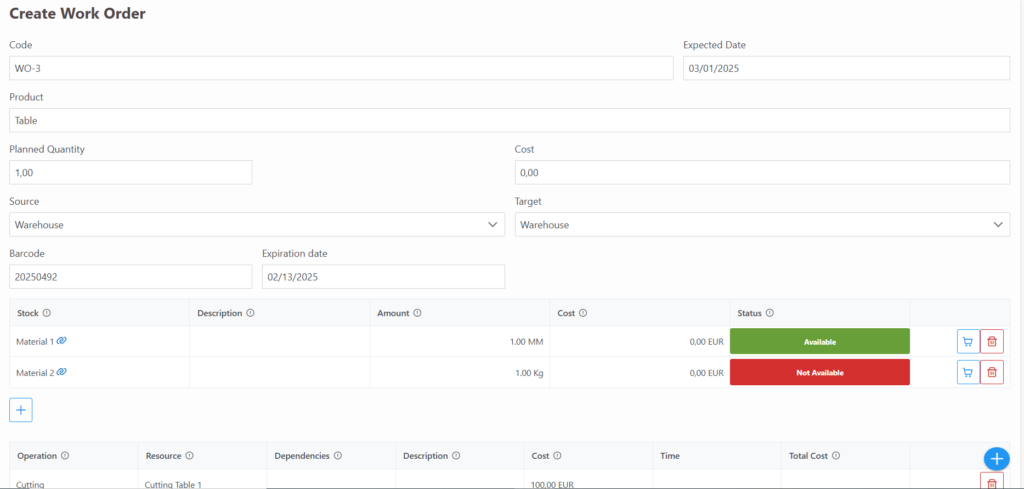

If the “Produce” button is clicked, Skala will automatically create and fill a work order for this order. In other words, a work order will be prepared for 3 units of Product 1, along with its recipe and the operations it will go through.

If the “Make for Batch” button is used, the option to make changes to the work order is also provided. Skala will first direct you to the work order creation screen, which will be pre-filled automatically, but the creation is finalized by clicking the save button.