Lot-based inventory tracking is a system commonly used to track the production and inventory processes of products using batch (lot) numbers.

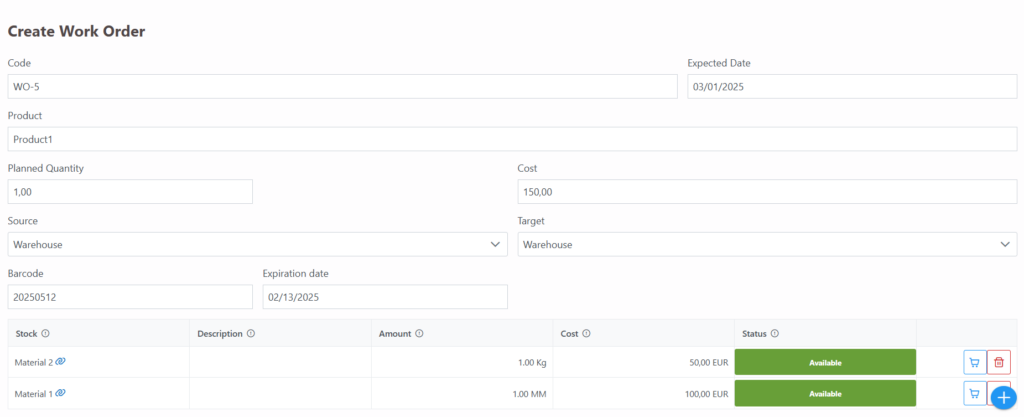

When a work order is created for a product with lot-based inventory tracking, the system automatically assigns a barcode and expiration date to the work order, which is different from the regular work order screen. These details can be modified through this screen.

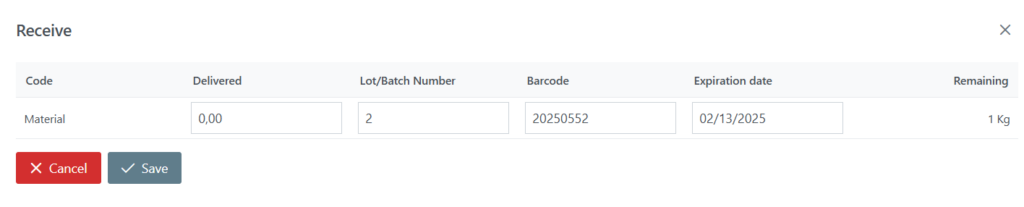

Similarly, when a purchase is made for raw materials with lot-based inventory tracking, the system automatically assigns a batch number and expiration date during the entry process. These details can also be modified during the receiving stage.

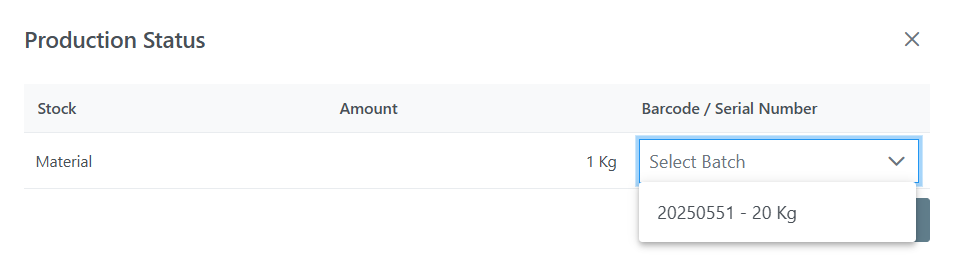

Later, when the work order is completed, the batch selection is made for the raw materials used.

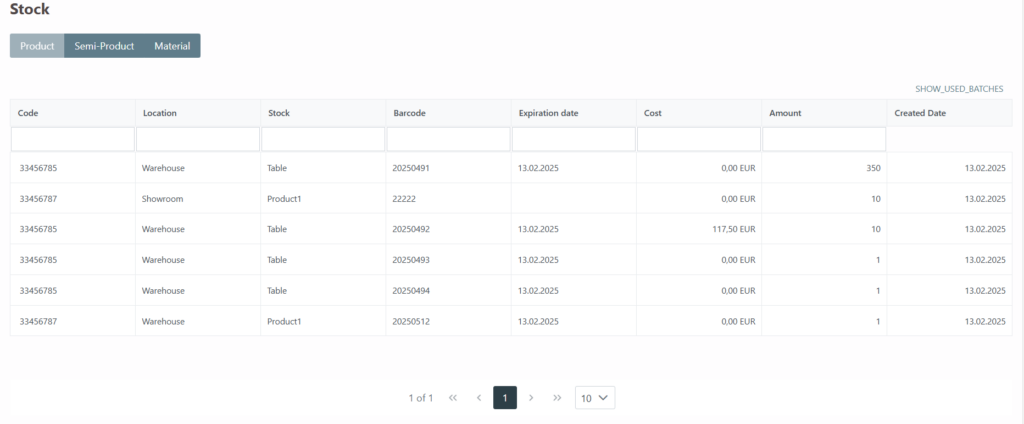

For tracking lot-based inventory, go to the inventory screen in the horizontal menu and select the “Batches” section from there.

This page contains details for inventory items that are tracked using lot-based inventory.