Inventory tracking is the process of regularly monitoring the quantity, location, and movements of a business’s products or raw materials. It ensures that businesses maintain the right amount of inventory, fulfill orders on time, and avoid unnecessary inventory costs. This process can be done manually but is often carried out more efficiently using automated inventory management systems and software.

Key Elements of Inventory Tracking

- Stock Movements: Recording the entries and exits of products at their respective locations.

- Stock Levels: Regularly monitoring the available quantity of a specific product.

- Alert Levels: Setting critical stock thresholds to avoid the risks of overstocking or understocking.

- Order Management: Planning and tracking supplier orders.

- Inventory Valuation: Calculating the cost of existing stock.

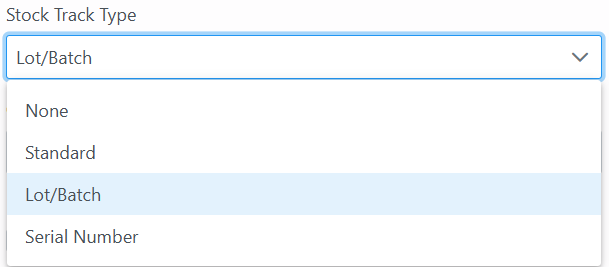

Skala MRP handles the above elements for you, but one crucial point is the method of inventory tracking. In your business processes, you can organize inventory tracking in Skala based on stock cards when creating a stock card.

Different inventory tracking methods are chosen based on the type of products and tracking needs of the business. The three main approaches used for this purpose are standard, lot-based, and serial number-based inventory tracking.

1. Standard Inventory Tracking

This method focuses on the product type and total quantity without individually identifying the products. Each product is assigned a specific stock code and quantity information.

Use Case:

Standard inventory tracking is typically preferred for low-cost products with minimal variability per unit (e.g., screws, nuts, paper).

2. Lot/Batch-Based Inventory Tracking

Lot-based inventory tracking monitors a group of products produced or supplied under a batch or lot number. Each lot usually represents a set of products with identical characteristics.

Use Case:

Commonly used in the food, pharmaceutical, or chemical industries to facilitate recall or quality tracking of products manufactured or received on a specific date.

3. Serial Number-Based Inventory Tracking

Serial number tracking involves monitoring each product with a unique serial number, allowing detailed tracking at the individual product level.

Use Case:

Widely used for electronic devices, machinery, valuable parts, and products requiring warranties.

By organizing your stock cards in Skala according to the method that suits your needs, the process will run much more smoothly.